CALL

612-708-4913

The Garage Floor Guy

Garage Floor Coatings

ABOUT US

In 1999 I began working with a Concrete Coating Manufacturer. My duties were two-fold, testing new products and training contractors. Through 2002 I was involved with monthly training seminars and continued to install products as a contractor. 2003 brought me to focus on the contracting business and www.ConcreteRenewal.com went live.

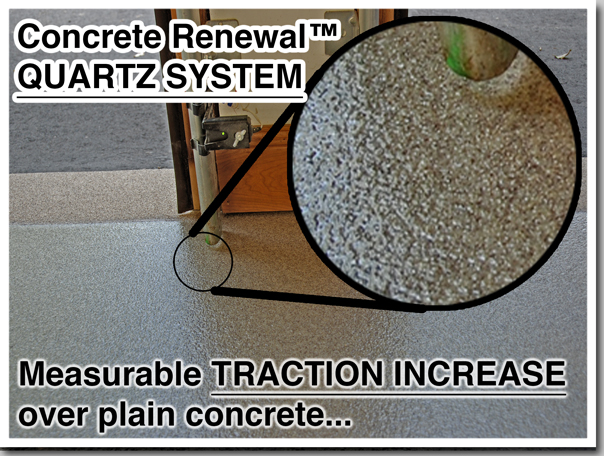

Working with all varieties of Concrete Coatings through this time one product seemed to be the Gold Standard for durability and safety, Quartz Concrete Resurfacer. Commmercial Customers required a surface that was regularily subjected to abuse from heavy equipment without wearing out like typical paint on coatings like Epoxy. Urathane and Polyaspartics did.

Residentially our customers chose this product for it's No-Slip Safety Texture, Durability and Beauty. The high demand for our Quartz Garage Floor Coating guided me to specialize in garage floor installations.

5 years into this venture my reputation was established and I was tagged with the name The Garage Floor Guy ... Throughout the Minneapolis/St. Paul metro area when someone was looking for a craftman for their project my name often came up including the Home Improvement Show Hometime. Dean Johnson (of Hometime) highlights products and services that add value to new or old houses. He contacted me and in 2007 taped my process from start to finish.

1-SET-UP AND CLIMATE CONTROL

Temperatures, Humidity and Dew Point have a significant affect on the ability of any coating to bond to the surface. Our Climate Control Trailer lets us stabilize air and surface temperatures, reduce humidity, dry out wet concrete, and eliminate problems with improper dew points. We install year round and we NEVER worry about cold, rain or snow. Also dust, sand and other contaminants are prevented from being blown onto the surface.

2-SURFACE PREPARATION

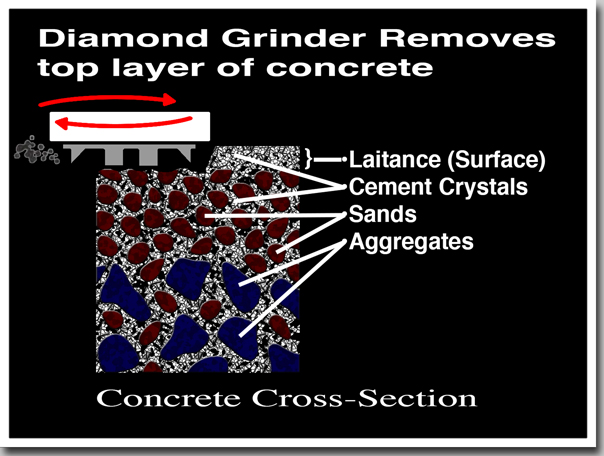

Surface preparation is the single most important factor in determining long term bonding performance of a concrete coating. At ConcreteRenewal Services we cut no corners. We have invested in the proper equipment to do all jobs right, the first time. To prepare a surface for any coating we literally remove the top layer 1/8th inch of concrete. This process removes contaminants and lets us apply our coating to a fresh clean surface.

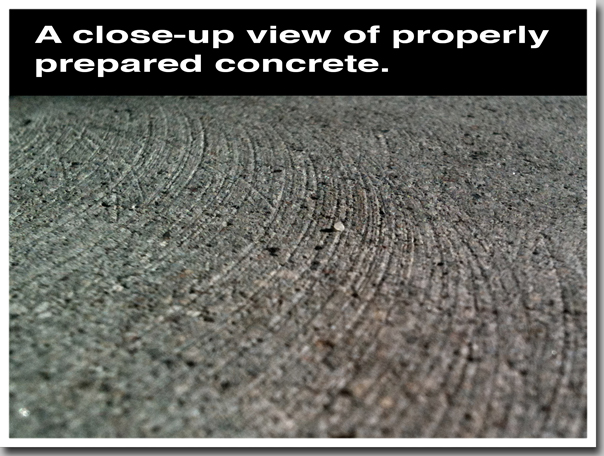

3-PROFILED SURFACE

With any coating, the bonding strength is dependent on an open, properly profiled surface. We achieve an open surface by removing the top layer (laitance) of concrete exposing the natural porosity of concrete and achieve the proper profile (surface texture) with our grinding machines...

4-PRODUCT APPLICATION - BASE COAT

Measurements are double checked as we need an exact square footage to mix the proper amount of resin. Mixed in 3 gallon batches, we mix and spread several batches to cover the floor. Spreading out the mixed resin and finishing with backrolling it in order to make sure it is even and consistent.

5-PRODUCT APPLICATION QUARTZ AGGREGATE

Unique to our application is the way we broadcast the quartz aggregate into the base layer of resin. While the resin is still in it's liquid state, we walk on the surface with spiked shoes as we start our quartz blowing machine. This machine will broadcast 700-800 pounds of quartz into the resin in a very consistant way. This control is the key to a consistant finish when the top coat gets applied.

5-PRODUCT APPLICATION TOP COAT

1-PRODUCT

We combine one of natures hardest minerals (quartz) with high quality resins selected to work in this environment. As an independent contractor, our flexibility to select product is not restricted. We have partnered with SIKA© Manufacturing to supply us with our product. SIKA© is the largest industrial floor coating resin manufacturer in the world providing unmatched product, unlimited selection and exceptional support.

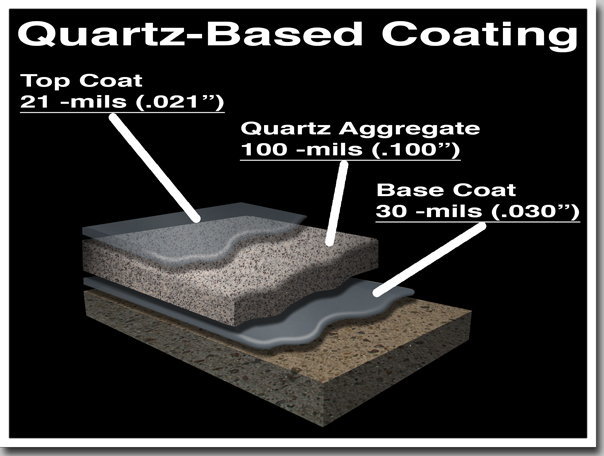

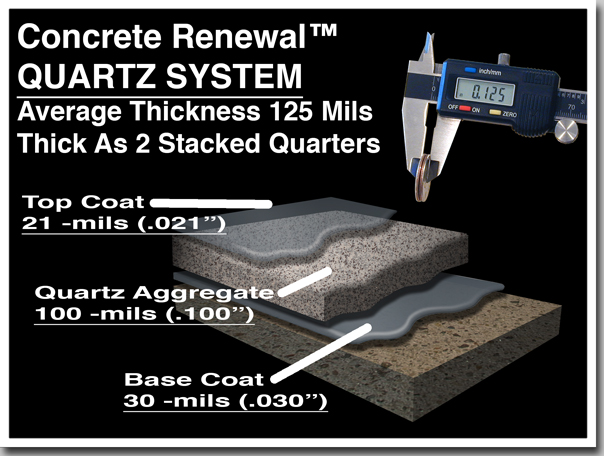

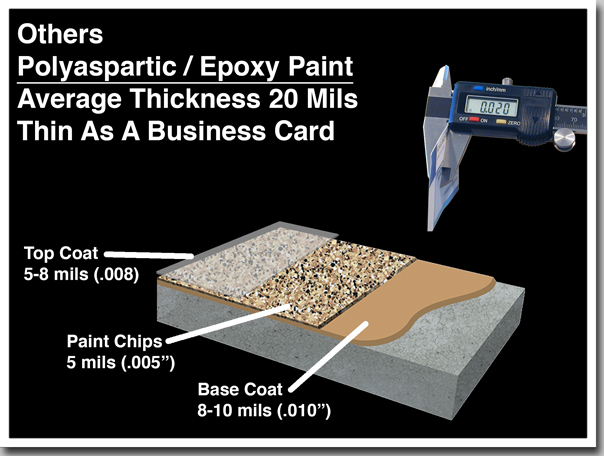

2-SIDE BY SIDE COMPARISON WITH OTHER SYSTEMS

As illustrated our coating is significantly thicker than the "Paint-On" products. This difference, along with quartz, results in a surface you can't wear through. The facts are "Paint-On" coatings are rarely thicker than a few sheets of paper or a business card.. Now combine the fact that you'll be driving a several thousand pound vehicle onto the surface, "Paint-On" coatings start to show their weakness.

3-SURFACE PROFILE/TEXTURE

In our climate, surface profile (texture) is a significant factor in what type of coating that should be installed. Floors are subject to water, snow and winters slop that gets brought into your garage for a significant percentage of the year.